Introduction

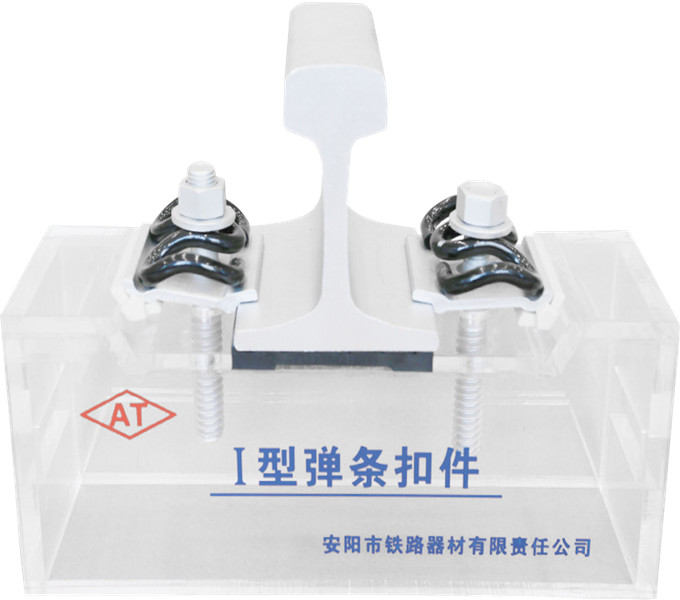

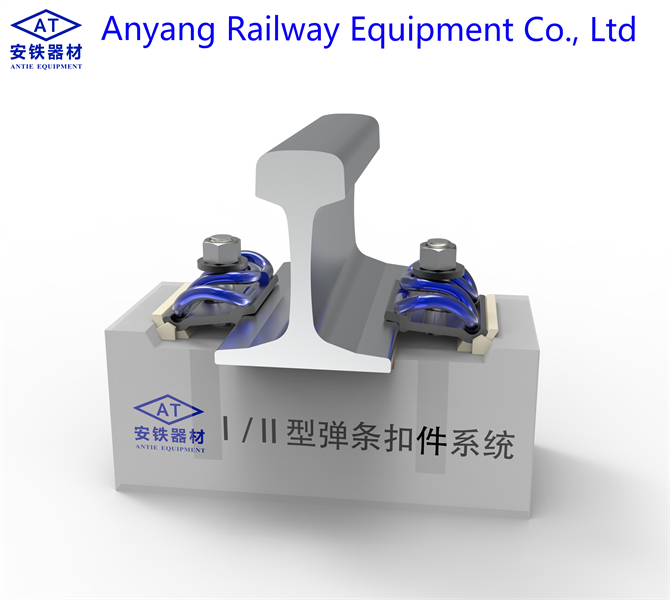

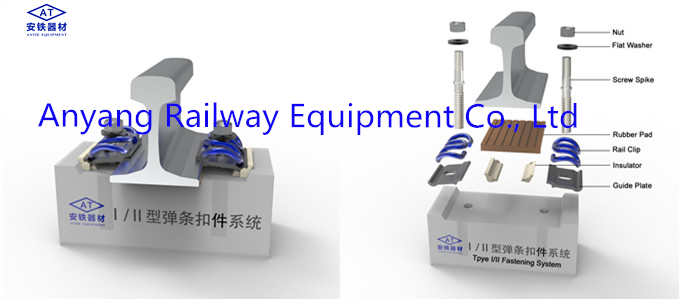

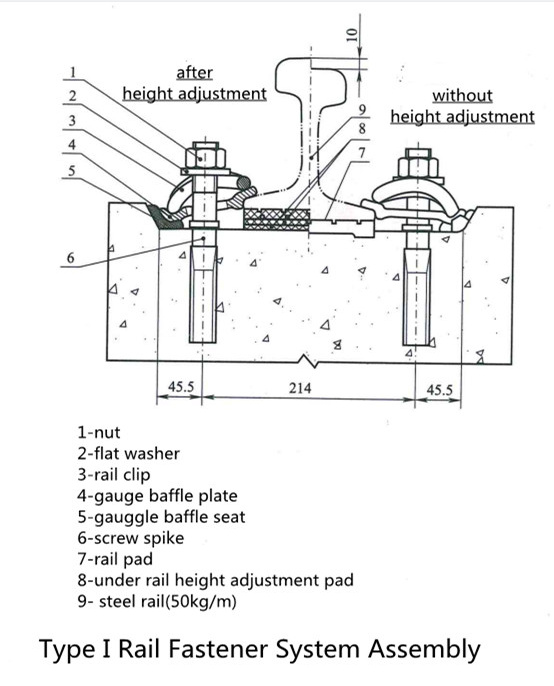

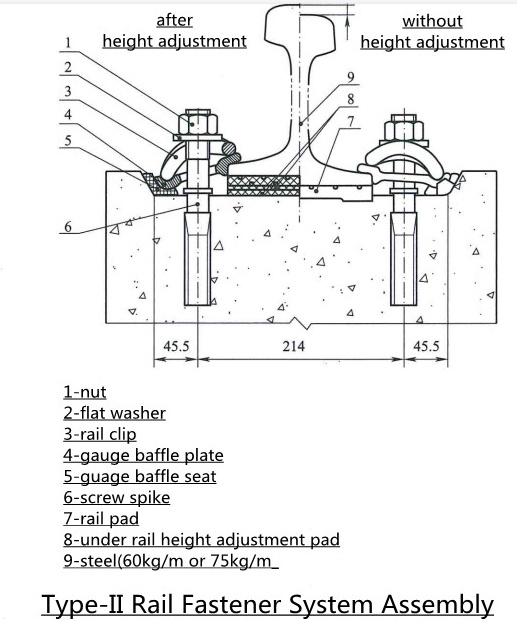

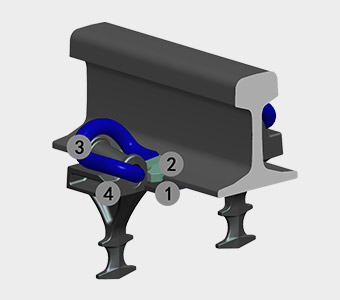

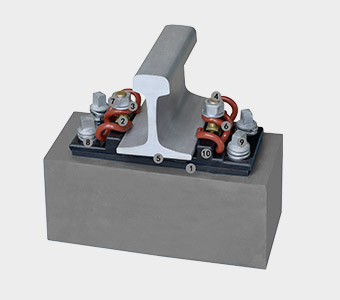

Type I rail fastening system is suitable for 50kg/m and 60kg/m rails that fixed on concrete shoulders, it’s unnecessary to be fixed with rail clamp, due to it has good elasticity, less force loss and better maintain the geometric shape of rail track, so I type rail fasteners have become the popular and main fasteners in Chinese railway with concrete sleepers.

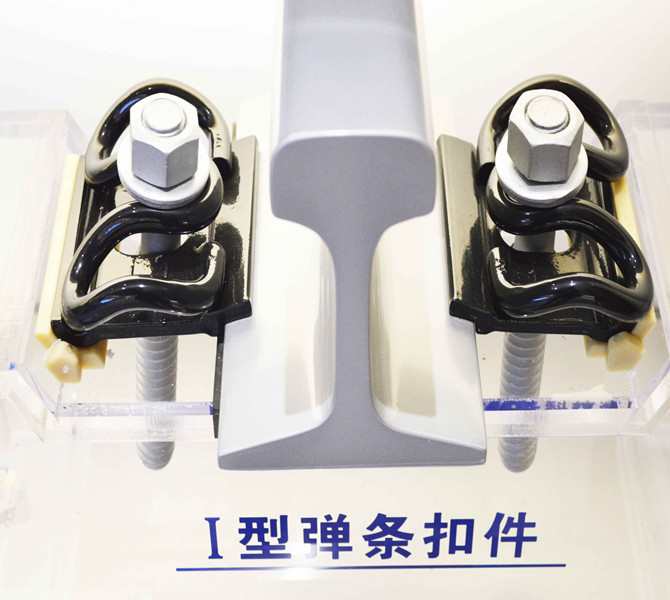

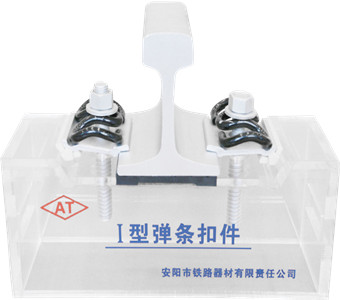

There are two types of elastic rail clips, A and B, their shape like ω, so I type rail fasteners also called ω fastener or ω-shaped elastic clips.

A type E-clip or B type E-clip is made of 60Si2Mn or 55Si2Mn hot-rolled spring steel bar, HRC 41-46, rail under the pad's static stiffness of 90 ~ 120kN / mm

There are two types of elastic rail clips, A and B, their shape like ω, so I type rail fasteners also called ω fastener or ω-shaped elastic clips.

A type E-clip or B type E-clip is made of 60Si2Mn or 55Si2Mn hot-rolled spring steel bar, HRC 41-46, rail under the pad's static stiffness of 90 ~ 120kN / mm