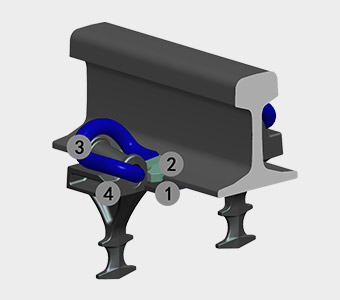

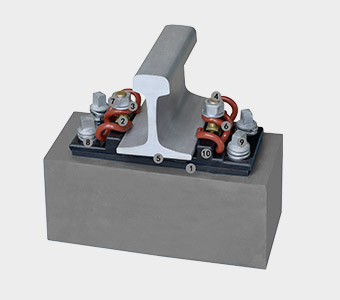

1. E2003 Rail Clip

1.1 Raw material: 60Si2Mn, its technical requirements comply with GB/T 1222.

1.2 Appearance: The elastic strip shall not have burrs that may affect operation or hinder assembly.

1.3 Dimensions: Comply with drawing design requirements.

1.4 Metallographic structure: The metallographic structure of the spring bar is uniform tempered troostite and tempered troostite. A trace amount of intermittent ferrite is allowed in the core, and it should comply with the regulations of TB/T 2478.

1.5 Buckling pressure: not less than 8.5KN.

1.6 Hardness: HRC44-48.

1.7 Fatigue performance: 3 million times without breaking.

1.8 Surface coating: The surface is treated with Dacromet anti-corrosion and has a neutral salt spray time of not less than level 9 for 500 hours.

2. Insulator

2.1 Raw materials: PA6-GF30

2.2 Appearance: The surface should be clean, smooth, consistent in color, without visible defects, pores or scorch marks, and without flash or burrs.

2.3 Dimensions: comply with drawing design requirements;

2.4 Water absorption conditioning: The drainage rate of the gauge block after water absorption conditioning shall not be less than 0.5%.

2.5 Hardness: not less than 110 HRR.

2.6 Internal voids: There must be no bubbles or voids inside the gauge block.

2.7 Impact toughness: When the temperature is 20±5℃, it shall not break after impact test.

2.8 Tensile strength

The lugs at both ends of the insulators shall not be damaged after being stretched and sheared by a force of 4.5 kN.

2.9 Insulation resistance: After boiling in 100℃ water for 2 hours, the insulation resistance value should be greater than Ω.

3. Rail pad

3.1 Raw material: HDPE.

3.2 Appearance: The pad under the rail should be black, clean and smooth.

3.3 Dimensions: should comply with the design drawings.

3.4 Density: 0.95g/cm³~0.98g/cm³.