The

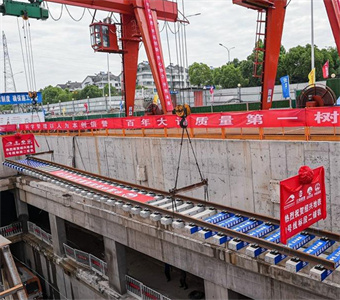

WJ-2 fastening system is a ballastless track fastening system developed to adapt to the laying of various shoulderless and ballastless tracks and meet the technical requirements of the passenger dedicated line fastening system. It is optimized on the basis of type 2 ballastless track fastener system. The WJ2 fastening system can be applied to embedded sleepers (double-block sleepers and long sleepers) and slab ballastless tracks on bridges, tunnels and roadbeds. Key technologies such as high elasticity, high insulation, strong structural versatility, small pressure attenuation and high fatigue strength of elastic clips, reliable connection with the foundation, large amount of adjustment of rail height and left and right positions, etc. need to be solved for the ballastless track fastener system of passenger dedicated line question.

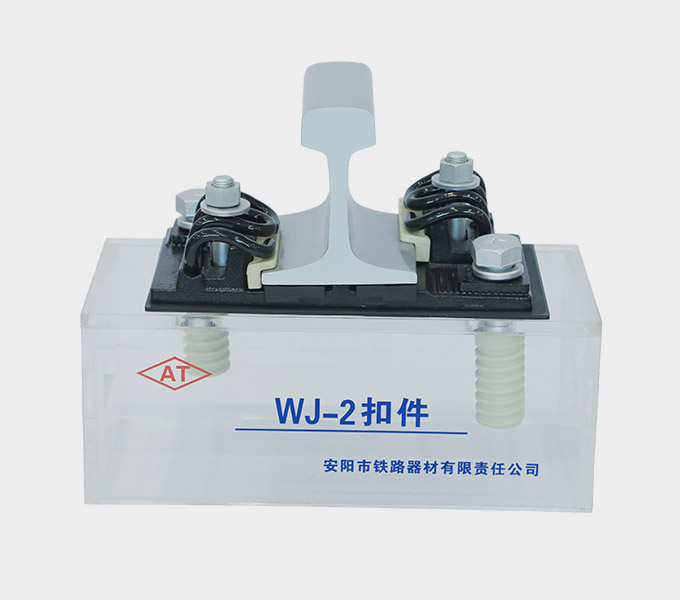

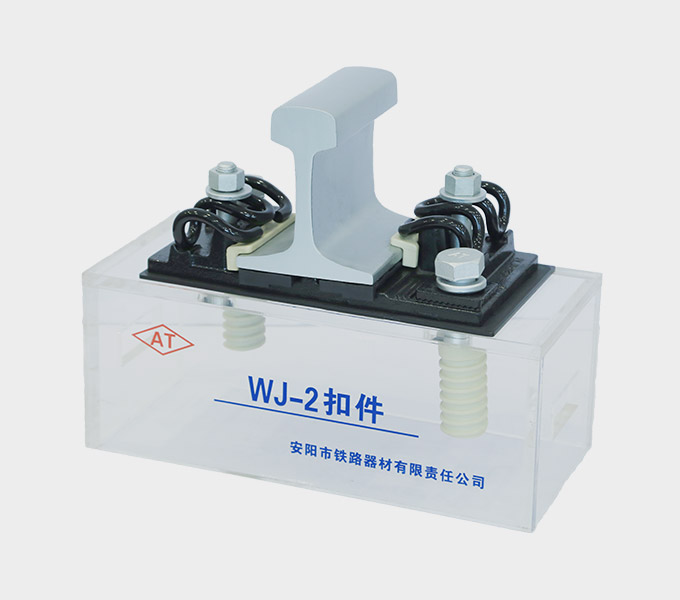

1. Composition Description and structural features of Type WJ-2 type Rail Fastening System:

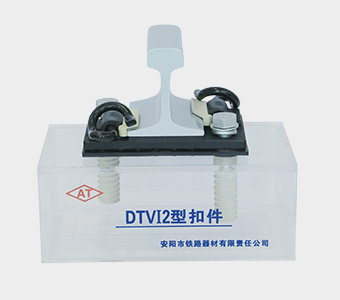

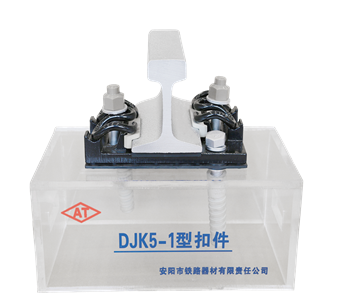

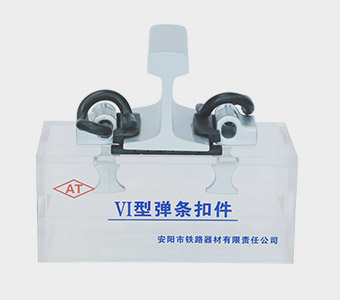

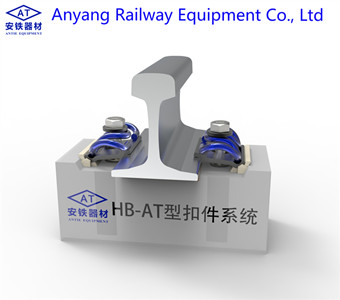

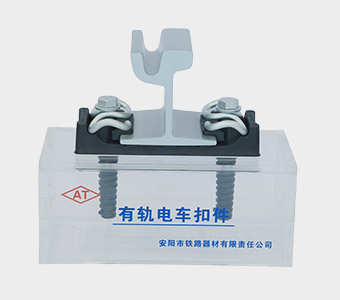

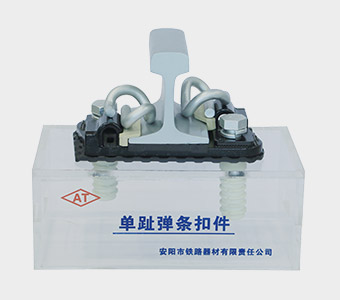

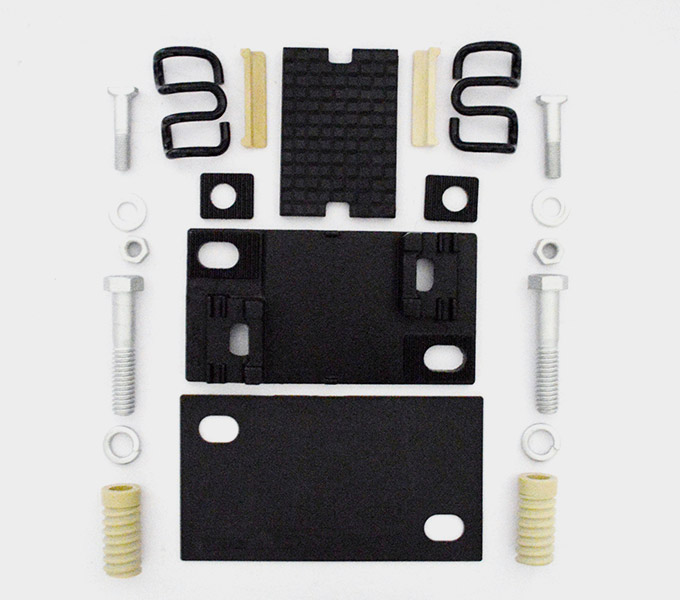

1) System composition

The fastener system consists of T-bolts, nuts, flat washers, spring clips, insulating blocks, iron pads, insulation cushioning plates, under-rail pads, anchor bolts, heavy-duty spring washers, flat cushions and dowels that positioning on concrete sleepers or rails. When adjusting the height of the rail, the height-adjusting pad (under rail and under iron pad) are used.

2) Structural features

This fastener system is a non-shoulder elastic clips structure with iron pads, with the following structural features:

a) Concrete sleepers or track slab bearing grooves do not have concrete shoulders, and the iron pad is equipped with a 1:40 rail bottom slope. The concrete sleepers or track slab bearing surface is flat slope, which can be used for sleepers (double-piece sleepers, long Sleeper) buried ballastless track can also be used for track slab ballastless track. The lateral load transmitted by the train is mainly overcome by the friction force of the iron pad.

B) A rubber pad is set between the bottom of the rail and the iron pad to realize the flexibility of the system. By replacing the under-rail pads of different stiffness, it can be adapted to the operating conditions of 350 km/h passenger dedicated line and 250 km/h passenger dedicated line (taking into account freight) respectively.

C) T-bolt insertion seat and steel rail shoulder are provided on the iron pad, and the spring clip is tightened by tightening the nut of the T-bolt. The matching design of the elastic clip has a larger elastic range than the existing elastic clips in our country (all kinds of elastic clips are 14 mm), and the fatigue strength is high. When the elastic pad under the lower rigidity rail is used, the buckle pressure of the elastic clip is less attenuated.

D) There is an insulating block between the rail shoulder and the rail on the iron pad to improve the insulation performance of the fastener system.

E) An insulating cushion plate is set between the iron backing plate and the concrete sleeper or track slab to buffer the impact of the train load on the concrete sleeper or track slab, and at the same time improve the insulation performance of the system. Protruding ribs and drainage ports are arranged around the insulating pad, which can effectively increase the water film resistance.

2. Technical paramters of Type WJ-2 type Rail Fastening System:

1) The height adjustment of the fastener system is 40mm, of which the adjustment under the rail is 10mm, and the adjustment under the iron plate is 30mm.

2) The adjustment amount of the fastener gauge is 20mm, that is, ±10mm. The gauge is adjusted by moving the iron pad with long round holes, which is a continuous stepless adjustment.

3) The maximum lateral force of the fastener is 40kN (fatigue load).

4) The torque of the T-bolt and nut is 70 to 90 N·m.

5) The tightening torque of the anchor bolts is 300 Nm.

6) The pullout resistance of the embedded insulating sleeve is greater than 100 KN.

7) The resistance between the rail and the bearing table is greater than 108Ω.

8) The stiffness of the fastener node is 40-60 KN/mm.

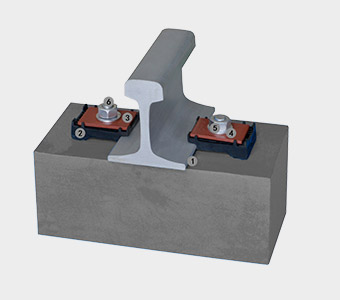

3. WJ-2 Fastening System Assembly

| No. |

Drawing No. |

Name |

Qty |

Material |

Weight or Volume |

| 1 |

Research line 9705(08)-3 |

T-Bolt |

2 |

45# |

0.684kg |

| 2 |

GB/T41 |

Nut M22 |

2 |

45# |

0.224kg |

| 3 |

TB/T1495.4-92 |

Flat washer 22 |

2 |

Q235-A |

0.138kg |

| 4 |

Research line 9705(08)-4b |

Joint rail clip |

2 |

60Si2MnA |

1.18kg |

| 5 |

Research line 1114-3a |

Rail plate |

1 |

thermoplastic polyester elastomer |

272cm3 |

| Research line 1114-4b |

Rubber plate |

thermoplastic polyester elastomer and Polymer wear-resistant material |

272cm3 |

| 6 |

Research line 1114-3a |

Type-I tie plate |

1 |

QT450-10 |

11kg |

| Research line 1114-4b |

Type-II tie plate |

QT450-10 |

11kg |

| 7 |

Research line 9705(08)-11 |

Elastic pad |

2 |

thermoplastic polyester elastomer |

405cm3 |

| 8 |

Research line 1114-6 |

Insulator |

2 |

Fiberglass Polyamide 66 |

93cm3 |

| 9 |

Research line 1114-7 |

Anchor bolt |

2 |

45# |

2.14kg |

| 10 |

GB7244 |

Heavy-duty spring washer 30 |

2 |

65Mn |

0.05kg |

| 11 |

Research line 1114-5a |

Type-I iron flat block |

2 |

QT450-10 |

0.58kg |

| Research line 1114-5b |

Type-II iron flat block |

QT450-10 |

0.50kg |

| 12 |

Research line 1114-8 |

Plastic dowel |

2 |

Fiberglass Polyamide 66 |

0.48kg |

| 13 |

Research line 1114-10 |

Height-adjusting plate under rail |

1 |

High-density polyethylene |

25.4cm3/mm |

| 14 |

Research line 1114-12 |

Height-adjusting plate under tie plate |

1 |

High-density polyethylene |

34.6cm3/mm |

.jpg)