Introduction

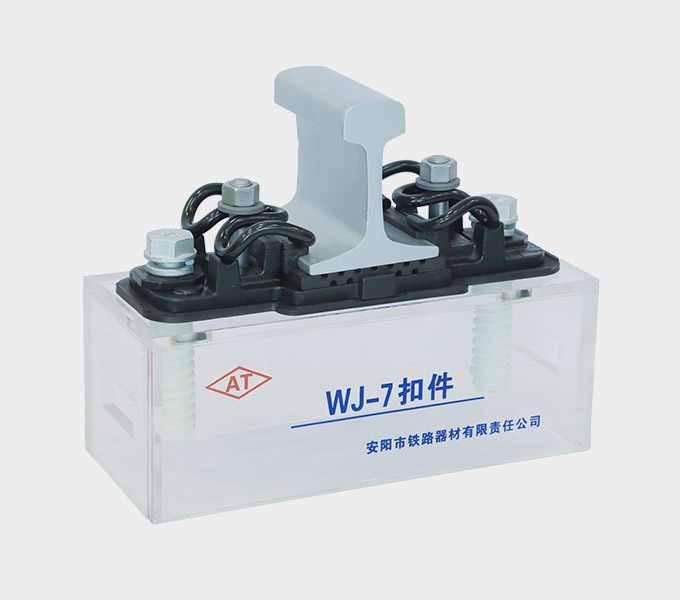

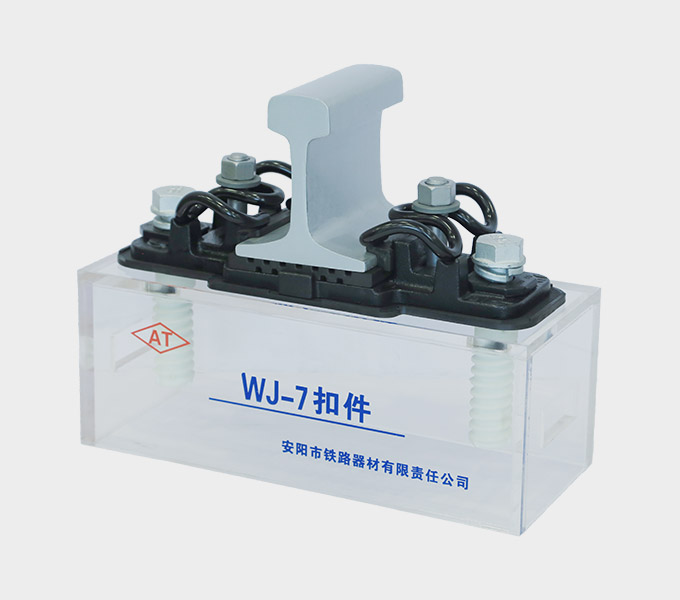

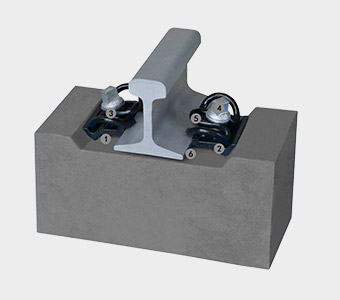

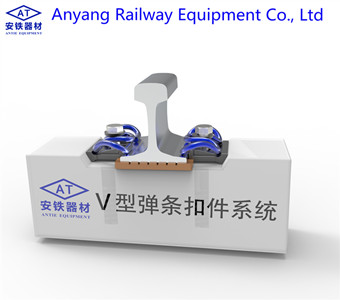

Type WJ-7 Rail Fastening System is a type of ballastless track fastener system developed to meet the technical requirements of the passenger dedicated line fastener system to adapt to the laying of various shoulderless and ballastless tracks. It is based on optimization of the original WJ-1 type and WJ-2 type ballastless track fastener system. The fastener system can be used in sleeper embedded (double-block sleepers and long sleepers) and slab ballastless tracks on bridges, tunnels and subgrades.

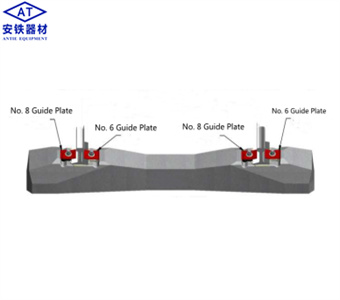

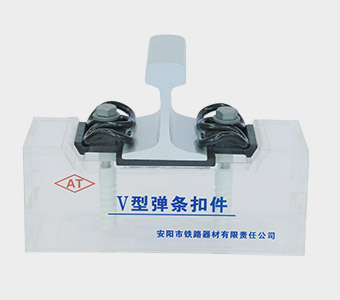

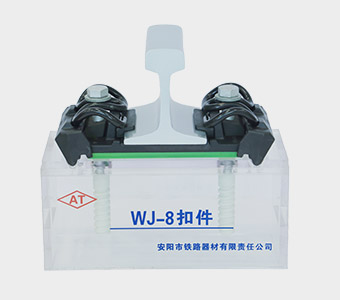

Type WJ-7 Rail Fastening System(also called Type WJ-7 elastic fastener), consists of T-bolts, nuts, flat washers, spring bars, insulating blocks, iron pad, insulation cushion pad, under-rail pad, anchor bolts, heavy spring washers, flat washers and it is composed of pre-embedded dowel positioned on concrete sleepers or track slabs. When adjusting the height of the rail, the height-adjusting pad (the adjusting height pad under rail adjusting height pad under iron pad) are used.

Type WJ-7 Rail Fastening System(also called Type WJ-7 elastic fastener), consists of T-bolts, nuts, flat washers, spring bars, insulating blocks, iron pad, insulation cushion pad, under-rail pad, anchor bolts, heavy spring washers, flat washers and it is composed of pre-embedded dowel positioned on concrete sleepers or track slabs. When adjusting the height of the rail, the height-adjusting pad (the adjusting height pad under rail adjusting height pad under iron pad) are used.