Tunnel Segment Connection Bolts Type

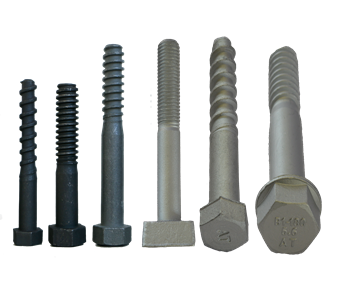

According to various factors such as the size of the segment, the diameter of the shield tunneling machine, and the location of the tunnel where the segment is located, the design of segment bolts is also diverse. At present, the main types of tunnel segment bolts are:

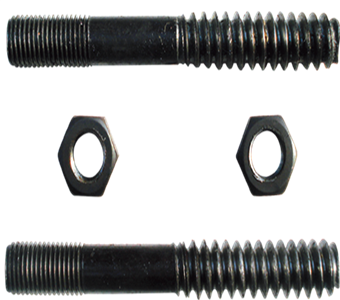

(1) Double-headed straight tunnel segment bolts

(2) Double-ended arc-shaped tunnel segment bolts

(3) Hexagonal arc tunnel segment bolts

(4) Hexagon head arc threaded tunnel segment bolts

(5) Hexagonal flange surface arc threaded tunnel segment bolts

(6) Non-standard tunnel segment bolts

Grade, Material and Surface Treatment of Tunnel Segment Bolts

Tunnel segment bolts, like other bolts and fasteners, are designed with different strength levels according to the application environment and different forces.

The commonly used grades are: 5.8, 6.8, and 8.8.

The corresponding production materials are: Q235, 45# steel, 40Cr and other materials.

Common surface treatments for tunnel segment bolts include hot-dip galvanizing (hot-dip galvanizing), Dacromet (commonly known as zinc-based Chromate), powder sherardizing, multiple composite powder sherardizing, etc. The quality of the surface treatment of the tunnel segment bolts is very important. Because the tunnel segment bolts are installed underground, they play a role in connecting the segments. The environment where it is located in humid, which can easily cause corrosion of bolts and cause rust. Therefore, if the surface treatment of the bolt fails to meet the design requirements, causing the bolt to rust during use, the corrosion to the inside of the bolt will affect the mechanical properties and tensile strength of the bolt. In relatively harsh environments, composite coatings, such as thermal spray zinc alloy or powder sherardizing + zinc-based chromate + alkali-resistant coating, can be used to enhance the corrosion resistance and alkali resistance of the product.

Mechanical and Physical Properties of Bolts and Studs

| No. |

Mechanical and Physical Properties |

Performance Level |

| 3.6 |

4.6 |

4.8 |

5.6 |

5.8 |

6.8 |

8.81) |

9.8 |

10.9 |

12.9 |

| d≤163) |

d>163) |

| 1 |

Nominal Tensile Strength |

N/mm2 |

300 |

400 |

500 |

600 |

800 |

800 |

900 |

1000 |

1200 |

| 2 |

Minimum tensile strength |

N/mm2 |

330 |

400 |

420 |

500 |

520 |

600 |

800 |

830 |

900 |

1040 |

1220 |

| 3 |

Vickers hardness HV F≥98N |

min |

95 |

120 |

130 |

155 |

160 |

190 |

250 |

255 |

290 |

320 |

385 |

| max |

2206) |

250 |

320 |

335 |

360 |

380 |

435 |

| 4 |

Brinell hardness HB F=30 D2 |

min |

90 |

114 |

124 |

147 |

152 |

181 |

238 |

242 |

276 |

304 |

366 |

| max |

2096) |

238 |

304 |

318 |

342 |

361 |

414 |

| 5 |

Rockwell hardness HR |

min |

HRB |

52 |

67 |

71 |

79 |

82 |

89 |

/ |

/ |

/ |

/ |

/ |

| HRC |

/ |

/ |

/ |

/ |

/ |

/ |

22 |

23 |

28 |

32 |

39 |

| max |

HRB |

95.06) |

99.5 |

/ |

/ |

/ |

/ |

/ |

| HRC |

/ |

|

32 |

34 |

37 |

39 |

44 |

| 6 |

Surface hardness HV 0.3 max |

/ |

7) |

| 7 |

Yield point N/mm2 |

Nominal |

180 |

240 |

320 |

300 |

400 |

480 |

/ |

/ |

/ |

/ |

/ |

| min |

190 |

240 |

340 |

300 |

420 |

180 |

/ |

/ |

/ |

/ |

/ |

| 8 |

Specified non-proportional elongation stress N/mm2 |

Nominal |

/ |

/ |

640 |

640 |

720 |

900 |

1080 |

| min |

/ |

/ |

640 |

660 |

720 |

940 |

1100 |

| 9 |

Guaranteed stress N/mm2 |

0.94 |

0.94 |

0.91 |

0.93 |

0.9 |

0.92 |

0.91 |

0.91 |

0.90 |

0.88 |

0.88 |

| 180 |

225 |

310 |

280 |

380 |

440 |

580 |

600 |

650 |

830 |

970 |

| 10 |

Breaking torque MB,N.m min |

/ |

according to GB/T3098.13 regulations |

| 11 |

Elongation after breaking % min |

25 |

22 |

/ |

20 |

/ |

/ |

12 |

12 |

10 |

9 |

8 |

| 12 |

rate of reduction in area % min |

/ |

52 |

48 |

48 |

44 |

| 13 |

Shock absorption work Aku,min |

|

25 |

|

30 |

30 |

25 |

20 |

15 |

| 14 |

Head firmness |

No break |

| 15 |

Minimum height of undecarburized thread E |

/ |

1/2H1 |

2/3H1 |

3/4H1 |

| 16 |

Maximum depth of fully decarburized layer G,mm |

/ |

0.015 |

| 17 |

Hardness after tempering |

/ |

The difference between the average hardness before and after tempering is not more than 20HV |

| 18 |

Surface defects |

According to GB/T 5779.1 or GB/T 5779.3 regulations |

The characteristics of tunnel segment bolts

The main feature of double-headed arc-shaped tunnel segment bolts is: compared with straight bolts, its arc-shaped form adds a bending process, such as improper process of the processing factory or the operator who does not pay attention to the details of the processing. It is easy to happen that the bolt cannot pass through the tube during installation due to the improper machining of the bolt radian. All arc-shaped products of Anyang Railway Equipment Co., Ltd. use molds to control the arc of the bolts, and each one passes the mold for inspection to ensure that each tunnel segment bolt that leaves the factory can pass through the segment smoothly. At the same time, it prevents the construction unit from During the construction process, it was found that the bolts could not pass through the segments, which affected the construction speed and helped the construction company reduce costs.

Application

Application

Anyang Railway Equipment Co., Ltd is a professional manufacturer of various segment bolts in mass production, the tunnel bolt production line is composed of all-solid-state IGBT heating equipment to heat the workpiece and automatic special thread rolling machine, the maximum output is 15,000 Pcs/day.

The segment bolts cases of Anyang Railway Equipment Co., Ltd:

1. Indonesia's Jakarta-Bandung high-speed railway: M36 tunnel segment bolts(50,300 sets)

2. Shijiazhuang Metro Line 2 Phase I: M36 tunnel segment bolts( 221,713 sets)

3. Chengdu Metro Line 10 and Phase 13: M30 tunnel segment bolts( 552,854 sets)

3. Dongguan Rail Transit Line 1 Phase I: M30 tunnel segment bolts( 159,976 sets)

4. Guangshan Railway: M30 tunnel segment bolts( 32,000 sets)

5. Fuzhou Rail Transit Line 5: M30 tunnel segment bolts(123,984 sets)

6. Xi'an Metro Line 16: M30 tunnel segment bolts( 186,700 sets)

7. Xiamen Metro Line 4: M30 tunnel segment bolts( 72,260 sets)

8. Guangzhou Metro Line 11: M24 segment bolts (33,800 sets)

9. Guangzhou urban rail transit: M24 tunnel segment bolts(70,456 sets)

10. Foshan Urban Rail Transit Line 3 : M24 tunnel segment bolts(145,200 sets)

11. Xi'an Metro Line 6: M27 tunnel segment bolts( 26,400 sets)

12. Underground comprehensive pipe gallery project in Guangzhou: M24 pipe segment bolts( 258,006 sets)

.jpg)