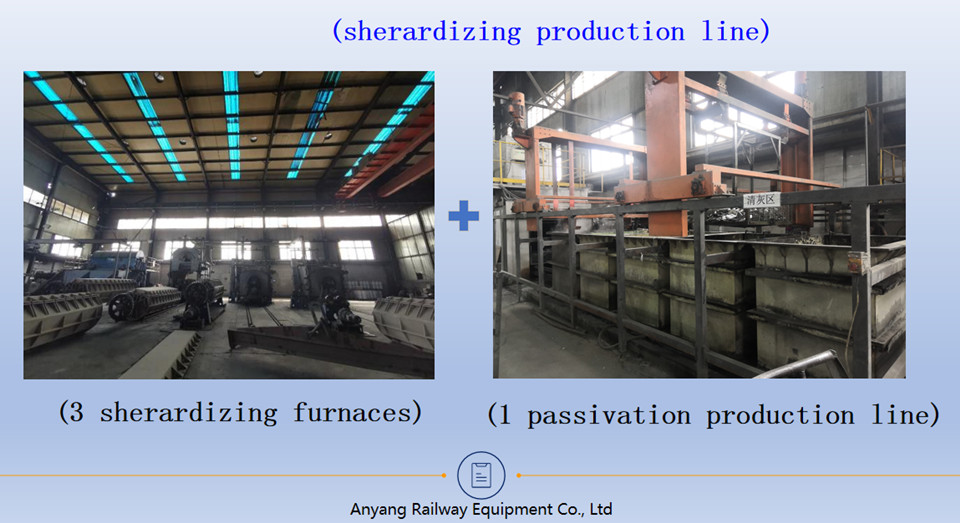

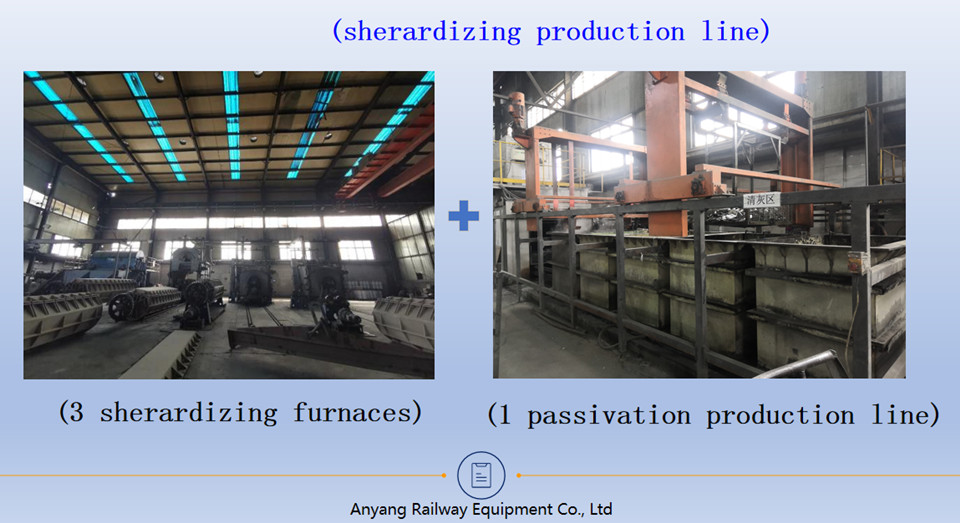

Sherardizing Production Line for Railway Rail Fasteners

Jun 05, 2021

Corrosion of fasteners

In the atmospheric environment, the railway fasteners are condensed by water vapor and adhere to the surface of the fasteners to form a film, which causes corrosion of the fasteners under the action of electrochemistry. Corrosion is more severe in coastal areas, acid rain areas and in tunnels.

Fastener anticorrosion background and purpose

1. High-speed railways, ordinary railways, and subways put forward higher requirements on the anti-corrosion performance of metal parts due to the high density of trains, fast speed, and short maintenance and repair operations, so as to prolong the service life of metal parts;

2. The corrosion of fasteners is an accumulation process from the surface to the inside. The performance of the fasteners will be affected as a whole due to the severe partial corrosion of the fasteners, and even the function of the fasteners will be lost.

Anti-corrosion method of railway fastener metal parts

1. Coating

Coatings of organic or inorganic compounds are applied to metal surfaces. Commonly used anti-corrosion processes include dipping, spray painting, electrostatic painting, and Dacromet.

2. Coating

Use other corrosion-resistant metals to form an anti-corrosion coating on the surface of the workpiece. Commonly used process methods are electroplating, hot-dip galvanizing, sherardizing, and mechanical galvanizing.

3. Chemical conversion film

Using chemical or electrochemical methods, a stable chemical film is formed on the metal surface. According to the film-forming medium, it is divided into: oxide film, chromate film, phosphate mold, etc.

4. Oiled

Anyang Railway Equipment Co., Ltd(AT) has a Sherardizing Production Line for Railroad Construction Materials, such as screw spikes, rail bolts, rail nuts, rail clamps, rail baffle plates, rail clips, etc.

Co-infiltration of zinc/zinc-nickel alloy is to place zinc, nickel active infiltration agent and metal workpiece in a closed container, and by heating to generate zinc, nickel and iron atoms interdiffusion to form a zinc-nickel infiltration layer on the surface of the workpiece The treatment process forms a zinc-nickel-iron alloy layer on the surface of the workpiece.

The multi-alloy co-infiltration production line is a chemical heat treatment process in which the workpieces are placed in a furnace containing various infiltrating elements, after eight-hour heating and heat preservation process, various elements are infiltrated into the surface of the workpieces. The surface of the workpieces have anti-corrosion properties such as high temperature resistance, corrosion resistance and wear resistance, and have obtained the PCA patent anti-corrosion technology jointly authorized by the Metal and Chemistry Research Institute of China Academy of Railway Sciences, China Railway Engineering Consulting Group Co., Ltd and China Railway Economic and Planning Research Institute. There are 3 sets of 3.5m heating body production lines, 3 sets of 5m heating body production lines, and 1 set of 6m heating body production line. Each production line has 3 furnaces. The maximum output in Anyang Railway Equipment Co., Ltd(AT) is 120 t/day.

In the atmospheric environment, the railway fasteners are condensed by water vapor and adhere to the surface of the fasteners to form a film, which causes corrosion of the fasteners under the action of electrochemistry. Corrosion is more severe in coastal areas, acid rain areas and in tunnels.

Fastener anticorrosion background and purpose

1. High-speed railways, ordinary railways, and subways put forward higher requirements on the anti-corrosion performance of metal parts due to the high density of trains, fast speed, and short maintenance and repair operations, so as to prolong the service life of metal parts;

2. The corrosion of fasteners is an accumulation process from the surface to the inside. The performance of the fasteners will be affected as a whole due to the severe partial corrosion of the fasteners, and even the function of the fasteners will be lost.

Anti-corrosion method of railway fastener metal parts

1. Coating

Coatings of organic or inorganic compounds are applied to metal surfaces. Commonly used anti-corrosion processes include dipping, spray painting, electrostatic painting, and Dacromet.

2. Coating

Use other corrosion-resistant metals to form an anti-corrosion coating on the surface of the workpiece. Commonly used process methods are electroplating, hot-dip galvanizing, sherardizing, and mechanical galvanizing.

3. Chemical conversion film

Using chemical or electrochemical methods, a stable chemical film is formed on the metal surface. According to the film-forming medium, it is divided into: oxide film, chromate film, phosphate mold, etc.

4. Oiled

Anyang Railway Equipment Co., Ltd(AT) has a Sherardizing Production Line for Railroad Construction Materials, such as screw spikes, rail bolts, rail nuts, rail clamps, rail baffle plates, rail clips, etc.

Co-infiltration of zinc/zinc-nickel alloy is to place zinc, nickel active infiltration agent and metal workpiece in a closed container, and by heating to generate zinc, nickel and iron atoms interdiffusion to form a zinc-nickel infiltration layer on the surface of the workpiece The treatment process forms a zinc-nickel-iron alloy layer on the surface of the workpiece.

The multi-alloy co-infiltration production line is a chemical heat treatment process in which the workpieces are placed in a furnace containing various infiltrating elements, after eight-hour heating and heat preservation process, various elements are infiltrated into the surface of the workpieces. The surface of the workpieces have anti-corrosion properties such as high temperature resistance, corrosion resistance and wear resistance, and have obtained the PCA patent anti-corrosion technology jointly authorized by the Metal and Chemistry Research Institute of China Academy of Railway Sciences, China Railway Engineering Consulting Group Co., Ltd and China Railway Economic and Planning Research Institute. There are 3 sets of 3.5m heating body production lines, 3 sets of 5m heating body production lines, and 1 set of 6m heating body production line. Each production line has 3 furnaces. The maximum output in Anyang Railway Equipment Co., Ltd(AT) is 120 t/day.