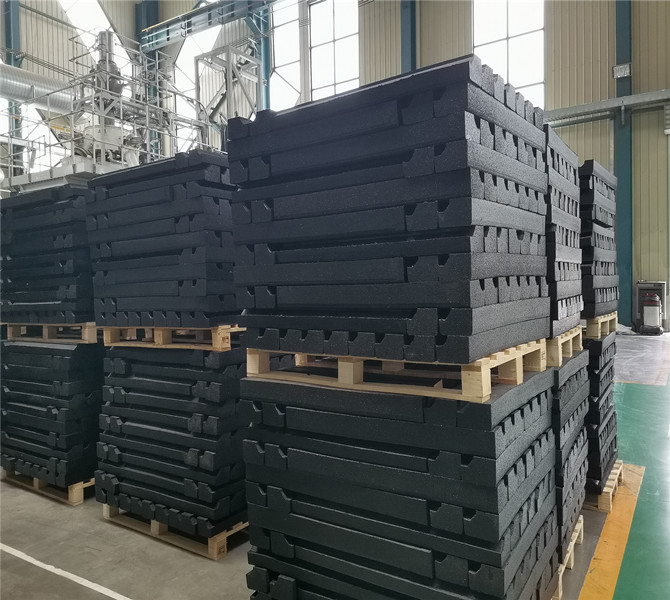

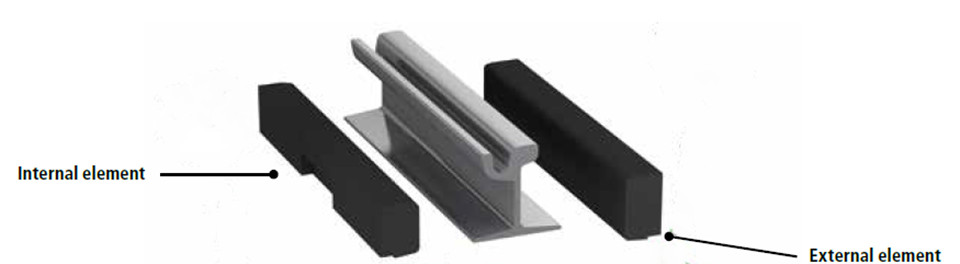

In recent years, in order to solve the problem of urban residents' travel and promote the construction of urban ecological civilization, because modern trams with features of low-carbon, environmentally friendly, and have a large passenger capacity have been developed rapidly in the world. But the trackside asphalt is often cracked and damaged due to repeated rolling by vehicles. In addition, because trams pass through densely populated urban areas, the environmental vibration caused by their operation has attracted widespread attention. One of the main reasons is that the rail waist protection block in the rail wrapping material is not strong enough to provide sufficient support for the road asphalt.

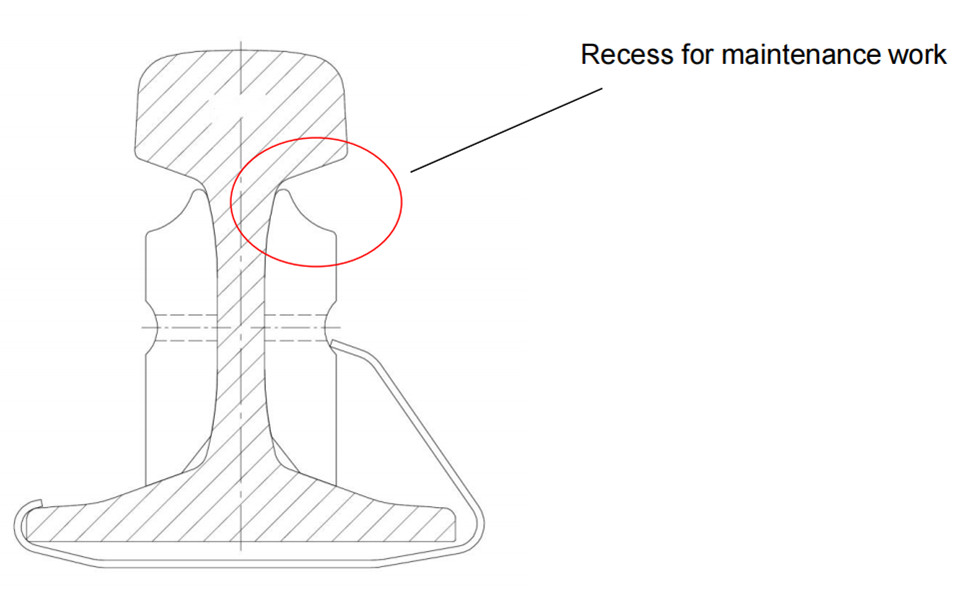

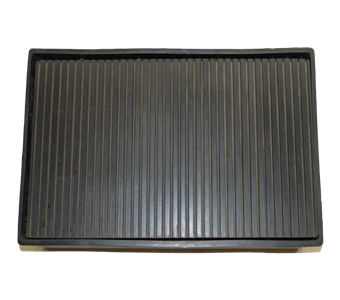

In order to reduce the impact of environmental vibration on residents and buildings near the track, the track structure of the tram ground line adopts the polymer chamber filling elements on the rail web, and usually plant grass above the track to achieve the effect of vibration reduction. In this way, When a tram passes by, the vibration between the wheels and the track will increase the buffer, the noise generated will be greatly reduced, the vehicle will run more smoothly, and the ride comfort will be higher.