1. Function:

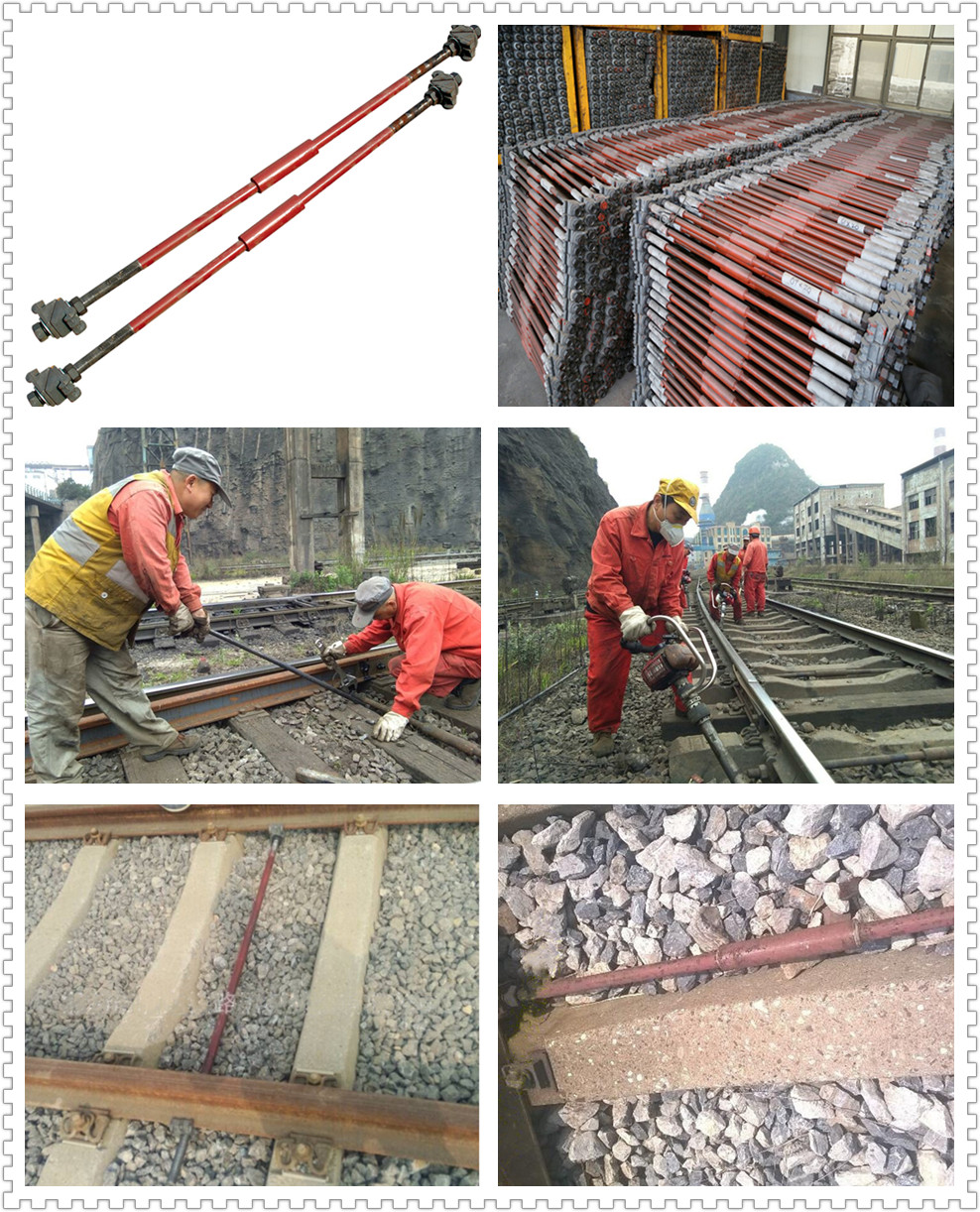

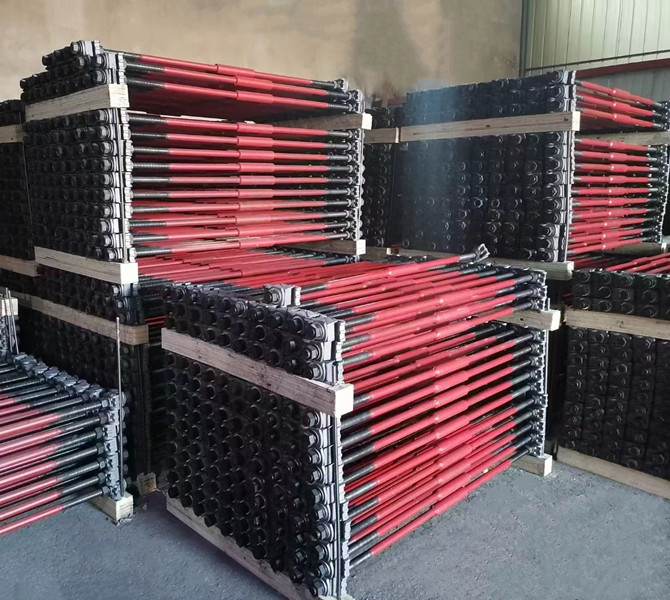

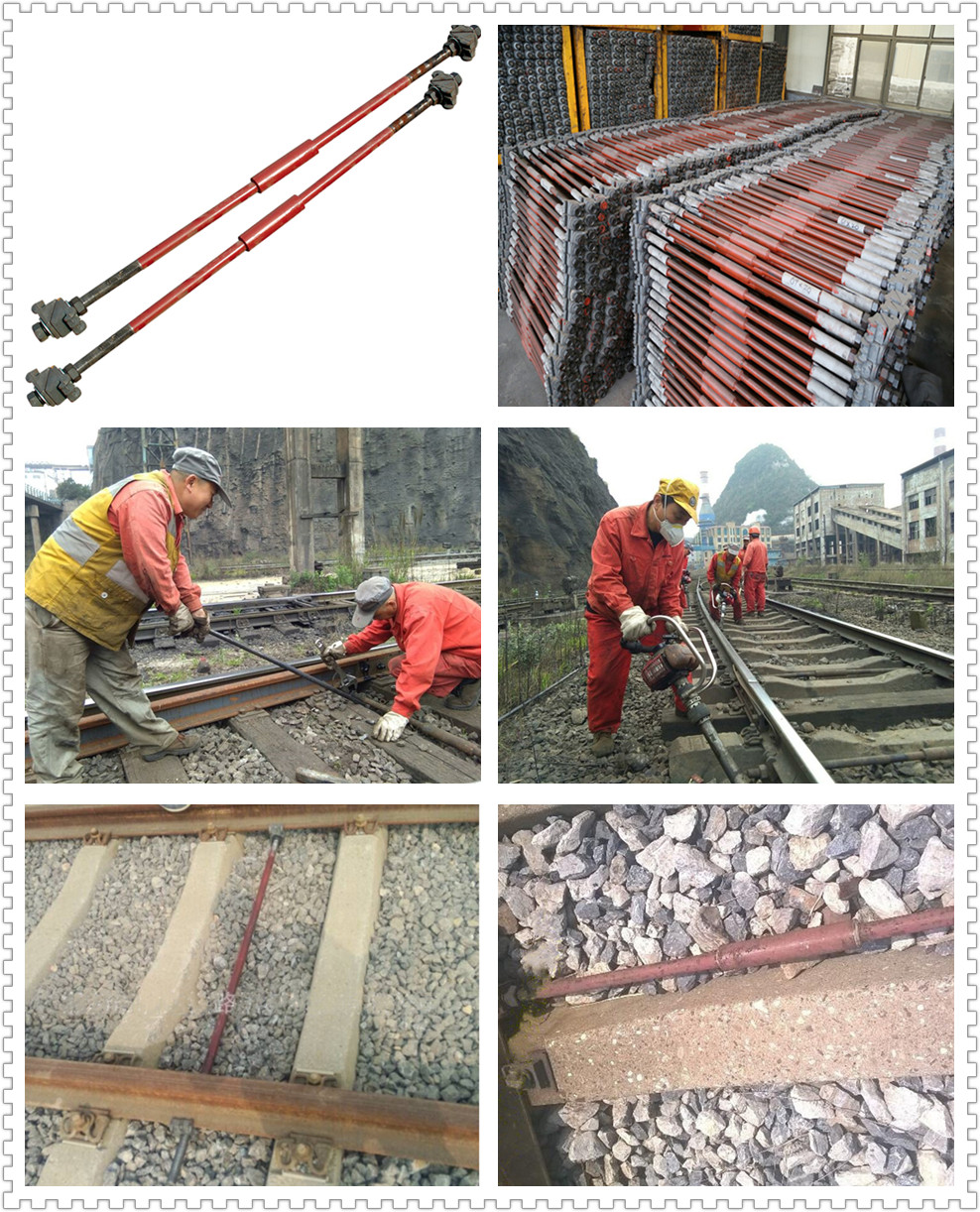

Generally, gauge tie rods are installed at weak points in the track, switches, bad ties, sharp curves, etc. The malleable jaws are made of a highly corrosive resistant material for long life.

Turnouts have the characteristics of complex structure, short service life, low driving safety, and heavy maintenance and repair work. They are one of the three weak links of track structure. Frequent maintenance and replacement of turnouts seriously affect the normal operation of heavy-duty railways.

Based on the rigid-flexible coupling method, a refined vehicle and turnout dynamic analysis model were established, and the reliability of the model was verified by combining the actual measurement results. The dynamic analysis model was used to study the effect of the turnout method and the driving speed on the dynamic characteristics of the turnout system. The law of influence, and the effect of three strengthening measures that can be taken on site are evaluated, and the following conclusions are drawn:

(1) When 20 sets of gauge tie rods are installed on the side stocks, the wheel-rail lateral force and wheel-rail vertical force can be reduced by 43.0% and 5.1% respectively. As the number of gauge rods increases, the indicators also decrease. Considering all factors comprehensively, it is recommended to install 10-14 sets of gauge tie rods on the side strand line in the turnout area.

(2) The use of a 1:20 rail bottom slope in the turnout area has a significant effect on reducing the wheel-rail force, in which the wheel-rail lateral force and wheel-rail vertical force can be reduced by 14.8% and 16.7% respectively.

(3) When the section width is increased by 2mm, the maximum increase in wheel-rail force and contact stress is 8.3%, and the maximum decrease in dynamic bending stress of the corresponding section is 18.8%.

When the train runs on a small radius curve (R=250m), the rails are subjected to various forces. In the direction of these forces, some elastic supports must be strengthened to prevent the rails from moving on the sleepers, tipping over and expanding the gauge. These elastic supports usually use gauge rods and rail supports.

2. Rail tipping

When the train runs on a small radius curve (R=250m), the rails are subjected to various forces. In the direction of these forces, some elastic supports must be strengthened to prevent the rails from moving on the sleepers, tipping over and expanding the gauge. These elastic supports usually use gauge rods and rail supports.

3. Maintenance

In the small radius curve section, in order to ensure the stability and reliability of the track structure, it is necessary to strengthen the track structure. From a safety perspective, the safety factor can reach 1.5 when the strengthened state reaches the state, and driving safety is guaranteed. However, with the failure of the strengthening components, the safety of the rail rollover coefficient is decreasing, reaching a minimum of 1.06. To ensure driving safety, the recommended safety factor is 1.15.

ambient temperature

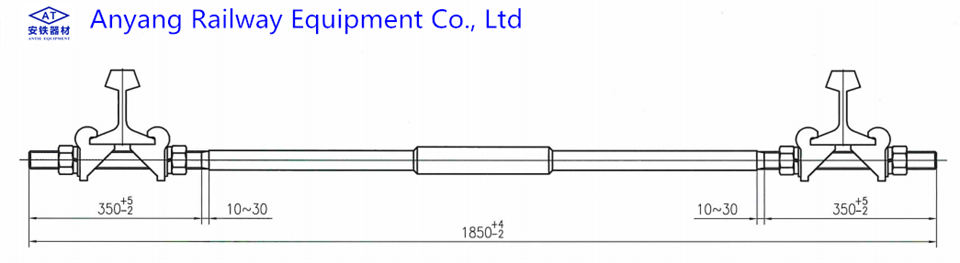

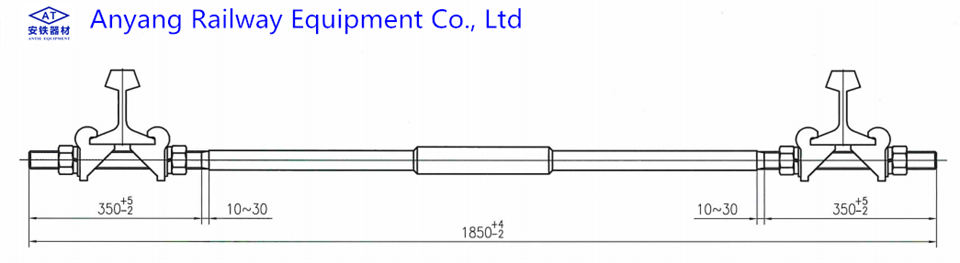

4. Specification

5. Ambient temperature

The insulated gauge rod is suitable for the ambient temperature -40℃~60℃.

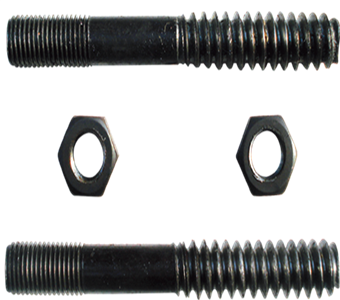

| No. |

Components |

Qty |

Specification |

Material |

Remark |

| 1 |

Rod |

1 |

M30, M36 |

Q235 |

|

| 2 |

Hex Nut |

4 |

M30, M36 |

Q235 |

GB/T 41 |

| 3 |

Flat Washer |

4 |

30,36 |

Q235 |

GB/T 95 |

| 4 |

Spring Washer |

4 |

30,36 |

65Mn |

GB/T93 |

|

5

|

Iron clamp

|

4

|

Type I

Type II |

KTH350-10

|

Suitable for 43kg/m, 50kg/m, 60kg/m steel rail |

| Suitable for 75kg/m steel rail |

6. Performance Requirements:

| Item |

Specification |

Value |

| Insulation performance |

Normal insulation resistance |

M30, M36 |

≥500MΩ |

| Damp insulation resistance |

M30, M36 |

≥0.25MΩ |

| Tensile performance |

Sample tensile failure load |

M30 |

≥245kN |

| M36 |

≥500kN |

| Fatigue life |

Sample cycle numbers |

M30, M36 |

200 Million |

| Tensile failure load of the sample after the test |

M30 |

≥240kN |

| M36 |

≥300kN |

| Normal insulation resistance of the sample after the test |

M30, M36 |

≥500MΩ |

| Damp insulation resistance of the sample after the test |

M30, M36 |

≥0.20MΩ |

| Appearance of each component after the test |

M30, M36 |

No damage such as rod sleeve detachment, permanent deformation, cracks, etc |

| Anti aging performance |

Tensile failure load of the sample after the test |

M30 |

≥240kN |

| M36 |

≥300kN |

| Normal insulation resistance of the sample after the test |

M30, M36 |

≥400MΩ |

| Damp insulation resistance of the sample after the test |

M30, M36 |

≥0.20MΩ |